In medical manufacturing, precision is not optional—it is mandatory. Blood collection

tubes must meet strict standards for sterility, dimensional accuracy, and material

integrity.

This article explores how precision mould engineering plays a vital role in ensuring

patient safety.

Why Precision Matters in Blood Collection Tubes

Blood collection tubes are used directly in clinical diagnostics. Any defect can lead

to:

- Sample contamination

- Leakage

- Incorrect test results

- Regulatory non-compliance

Critical Precision Requirements

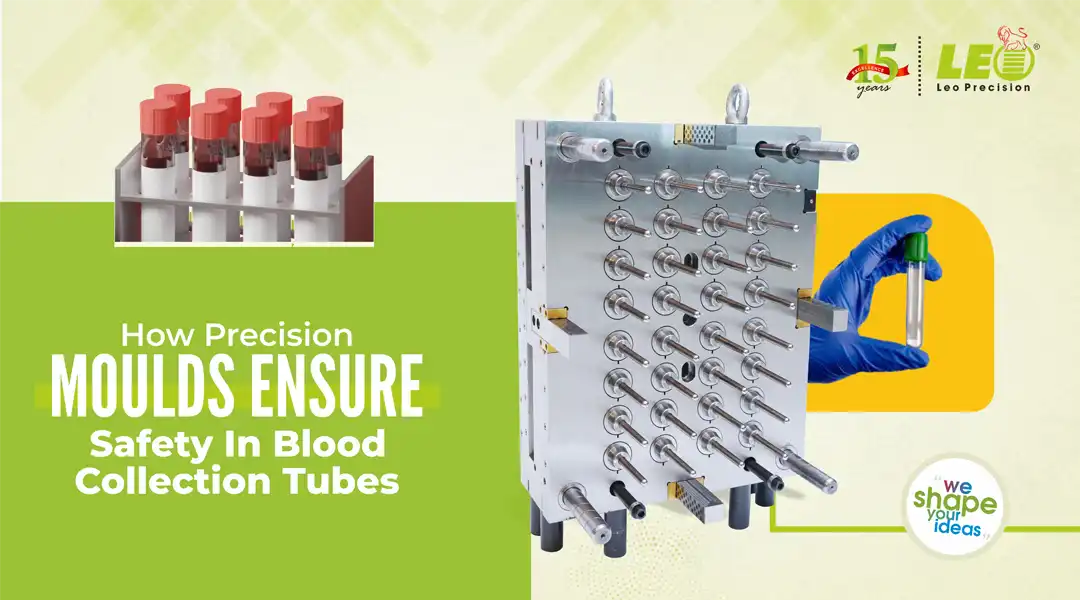

Injection moulding is a manufacturing process where molten plastic is injected into a

closed mould cavity, cooled, and ejected as a solid part.

1. Dimensional Accuracy

- Exact inner diameter for vacuum control

- Consistent tube length and wall thickness

- Perfect cap sealing interface

2. Surface Finish Quality

- Ultra-smooth internal surfaces

- Prevents blood clotting or residue buildup

- Enables accurate lab analysis

3. Material Flow Consistency

- Uniform filling avoids weak spots

- Prevents micro-cracks

- Ensures structural integrity

Role of Precision Injection Moulds

High-precision moulds ensure:

- Tight cavity tolerances

- Balanced runner systems

- Stable cycle-to-cycle repeatability

Advanced mould designs integrate:

- Precision-machined cores

- Optimised cooling channels

- Medical-grade hot runner systems

Compliance with Medical Standards

Precision moulds support compliance with:

- ISO medical packaging norms

- GMP manufacturing requirements

- International diagnostic regulations

Consistency in moulding directly translates to reliable, safe medical devices.

Conclusion

Precision mould engineering is the foundation of safe medical disposables. In blood

collection tubes, accuracy at the micron level safeguards patient health and ensures

trust in diagnostic results.