In the world of packaging, every detail matters. Among the myriad of components

that ensure a product’s safety and usability, caps and closures play a pivotal

role. These small yet critical components are not just about sealing a

container; they are about maintaining packaging integrity, ensuring product

safety, and enhancing consumer experience. Central to their creation are

precision-engineered moulds that redefine how caps and closures are

manufactured.

The Role of Caps and Closures in Packaging

Caps and closures serve multiple functions, including:

-

Product Protection: They create an airtight seal that

prevents contamination, leakage, and spoilage.

-

User Convenience: Ergonomic designs make opening and

resealing containers easier for consumers.

-

Brand Appeal: Customized shapes, colors, and branding on

closures can elevate a product’s market presence.

-

Regulatory Compliance: Tamper-proof designs ensure consumer

safety and meet industry standards.

How Moulds Drive Precision in Caps and Closures

The manufacturing of caps and closures relies on high-quality moulds that ensure

consistency, durability, and efficiency. Here’s how these moulds define the

packaging process:

1. Precision Engineering

Moulds are designed to produce caps and closures with tight tolerances,

ensuring that every piece fits perfectly onto its container. This precision

minimizes defects and enhances sealing performance.

2. Versatility in Design

Modern moulding techniques allow for intricate designs that cater to various

industries, from child-resistant closures for pharmaceuticals to flip-top

caps for personal care products. The ability to customize moulds ensures

that the packaging aligns with the product’s unique requirements.

3. Material Optimization

Caps and closures are often made from lightweight yet durable materials such

as PET, HDPE, or PP. Advanced moulds support these materials, reducing waste

while maintaining strength and functionality.

4. High-Volume Production

State-of-the-art moulds are built for efficiency, enabling high-speed

production lines to churn out millions of caps and closures without

compromising quality. This capability is crucial for industries with

high-demand products.

Applications of Caps and Closures Moulds

-

Beverage Industry:

Producing caps for carbonated

drinks, water bottles, and juices that ensure freshness and prevent leakage.

-

Pharmaceuticals:

Manufacturing tamper-proof and

child-resistant closures for medicines and syrups.

-

Cosmetics and Personal Care:

Designing aesthetically

pleasing caps for creams, shampoos, and lotions.

-

Household Products:

Creating robust closures for

detergents, cleaners, and other household goods.

Innovations in Caps and Closures Moulds

The moulding industry continues to evolve with advancements such as:

-

Multi-Cavity Moulds: Increasing output without additional production costs.

-

Hot Runner Systems: Enhancing efficiency and reducing waste in moulding

processes.

-

Sustainability Features: Supporting the use of biodegradable and recycled

materials.

-

Smart Closures: Integrating tamper indicators and dispensing mechanisms for

added functionality.

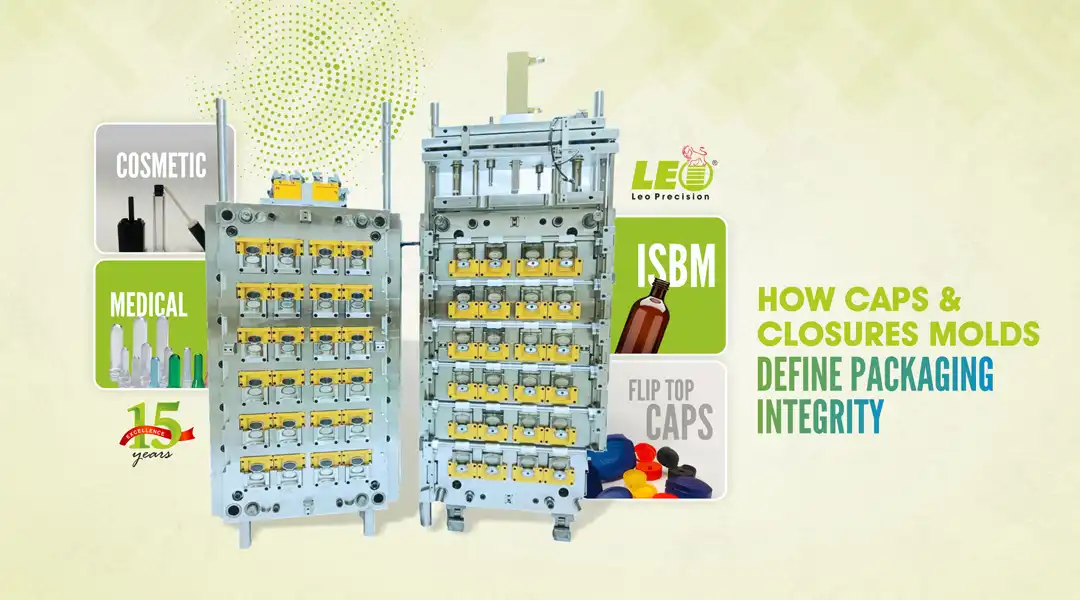

Ensuring Packaging Integrity with LEO Precision

At LEO Precision, we understand the critical role caps and closures play in

packaging. Our cutting-edge moulds are engineered to deliver unmatched quality

and performance, tailored to meet the unique needs of various industries. By

investing in our moulding solutions, you’re ensuring packaging integrity that

protects your product and delights your customers.

Conclusion

Caps and closures are much more than simple components; they are guardians of

packaging integrity. Precision moulds are the backbone of their production,

ensuring they meet the demands of modern consumers and industries. With the

right moulding solutions, manufacturers can achieve excellence in packaging that

drives brand loyalty and product success. Trust LEO Precision to be your partner

in delivering perfect fits for every packaging need.