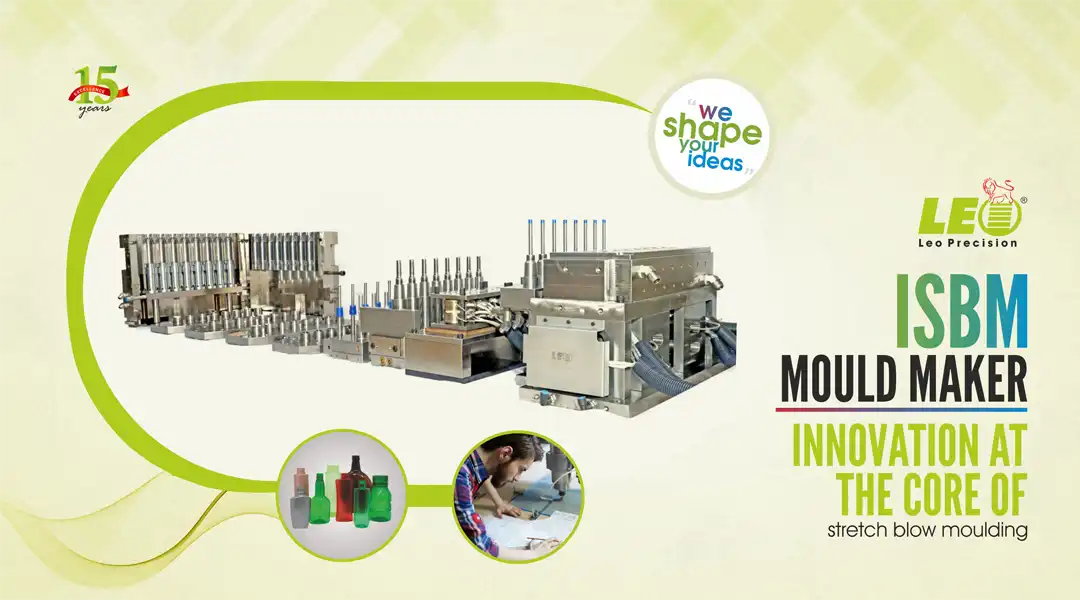

Injection Stretch Blow Moulding (ISBM) is a versatile process known for

producing lightweight, high-clarity, and durable PET containers. As a premier

ISBM mould maker, Leo Precision delivers tooling that ensures precision,

consistency, and productivity, no matter how complex your packaging requirement

may be.

ISBM Moulds: Where Science Meets Speed

ISBM is ideal for packaging where both form and function matter. From pharma

bottles with precise neck finishes to liquor bottles with unique shapes, our

ISBM moulds are designed to deliver:

-

Uniform wall thickness.

-

Improved mechanical strength.

-

High clarity and gloss.

-

Faster cycle times with advanced cooling.

Built for Demanding Environments

Leo Precision moulds are compatible with leading ISBM platforms, including ASB,

SIPA, and MHT, and support both single-stage and two-stage operations. Each

mould is crafted using:

-

High-hardness stainless steel.

-

Mirror-polished cavity surfaces.

-

Dynamic temperature control for consistency.

Total Support, from Design to Deployment

Whether you’re launching a new product or upgrading existing lines, our team

provides:

-

Design consultation and prototyping.

-

Custom cavity and neck finish configurations.

-

Post-installation support and servicing.

Conclusion

With the global push toward sustainable, lightweight packaging, ISBM moulds from

Leo Precision are a strategic investment in quality, efficiency, and

differentiation.