In the world of packaging, PET (Polyethylene Terephthalate) has become the gold

standard. The demand for PET bottles has skyrocketed especially in beverages,

edible oils, cosmetics, household cleaners, and pharmaceuticals. At the center

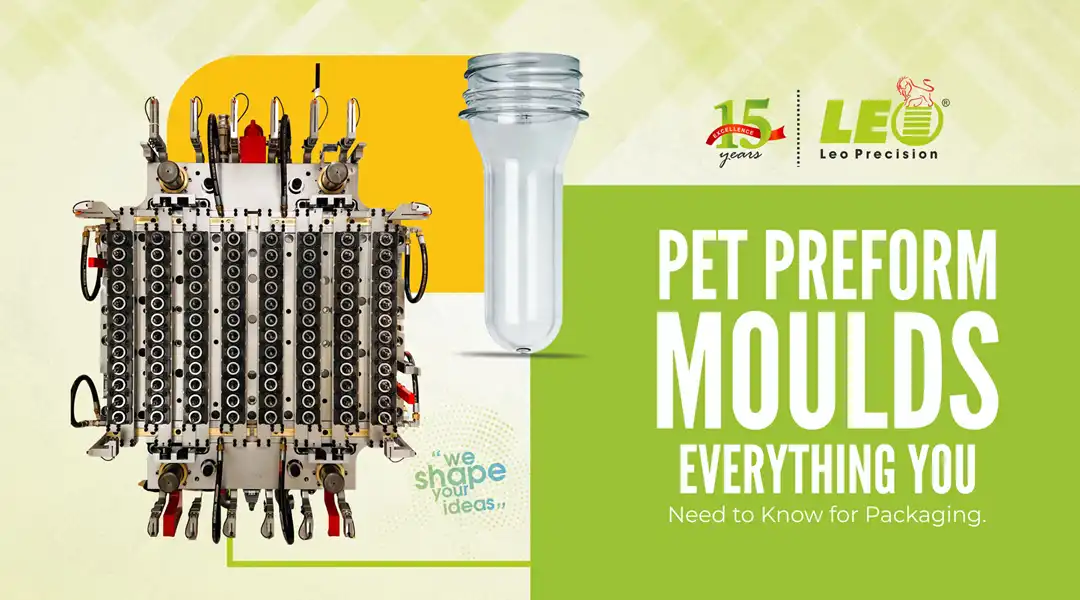

of this booming industry are PET preform moulds, the heart of every

bottle-making operation.

What Are PET Preforms?

PET preforms are the intermediate product used to manufacture PET bottles

through a process called stretch blow moulding. These small,

test-tube-like shapes are produced using injection moulding.

Why PET Preform Moulds Matter

PET preforms are the intermediate product used to manufacture PET bottles

through a process called stretch blow moulding. These small,

test-tube-like shapes are produced using injection moulding.

- Bottle quality

- Neck finish accuracy

- Cycle time

- Output efficiency

- Material distribution

- Durability of the production line

Key Features of High-Quality PET Preform Moulds

-

1. High Cavitation Options (24–96 cavities) – For maximum

productivity.

-

2. Hot Runner Systems – To maintain optimal melt temperature

and reduce waste.

-

3. Superior Cooling Channels – For faster cycles and consistent

weight distribution.

-

4. Precision Neck Finish – Ensures perfect sealing for

carbonated and non-carbonated drinks.

-

5. Durable Steel Grades – Enhances mould life and reduces

maintenance.

Choosing the Right Mould Manufacturer

Consider

-

Experience with ASB, SIPA, and Husky systems

-

Custom cavity configurations

-

Material expertise

-

After-sales support and maintenance

-

Proven performance and customer history

Applications of PET Preform Moulds

- Mineral water bottles

- Soft drink bottles

- Juice & milk bottles

- Edible oil containers

- Liquor and household product bottles

- Cosmetic containers

Investing in a high-quality PET preform mould is not an expense, it’s a long-term

asset for your packaging business.