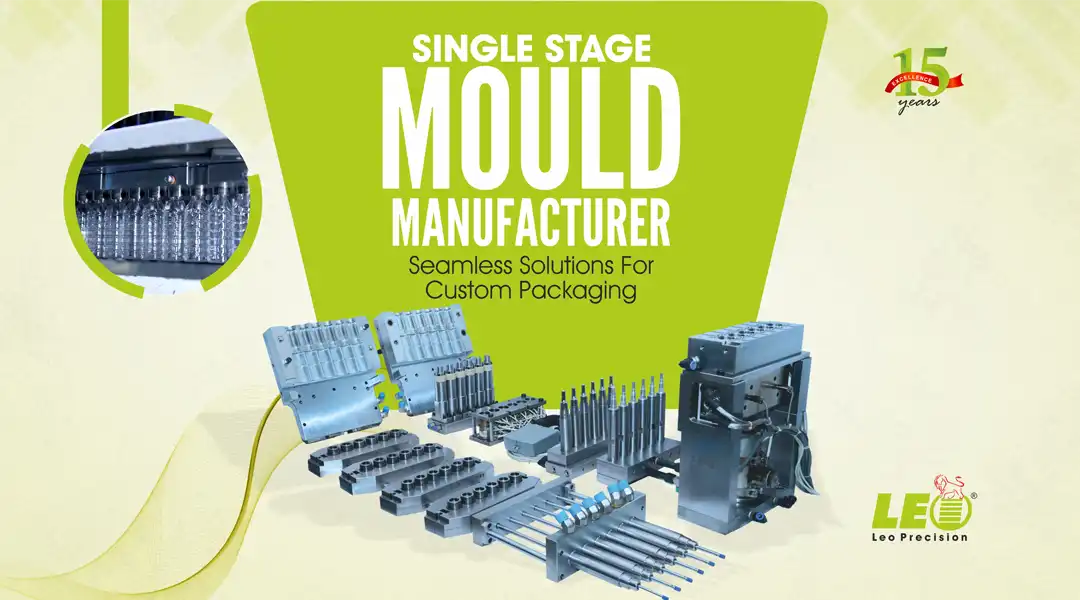

As packaging demands grow more complex and customized, single-stage PET moulding

has emerged as a cost-effective, flexible, and efficient solution. At Leo

Precision, we are proud to be among India’s leading single stage mould

manufacturers, serving niche applications across cosmetics, liquor,

pharmaceuticals, and specialty beverages.

Understanding the Single-Stage Advantage

In a single-stage process, preform and container are formed in one continuous

cycle, eliminating the need for reheating and rehandling. This leads to:

-

Enhanced clarity and material distribution.

-

Reduced energy consumption.

-

Faster product development cycles.

-

Ideal for shorter production runs and customized designs.

Expertise Across Platforms

Our moulds are precisely tailored for use in ASB machines and compatible

platforms, ensuring seamless operation and superior results. With Leo

Precision’s single-stage moulds, you can expect:

-

Accurate neck and body geometry.

-

Strong mechanical properties.

-

Reduced flash and waste.

-

Long mould life with easy maintenance.

Innovation with Every Cavity

From intricate perfume bottles to sturdy liquor containers, we combine design

expertise and robust engineering to develop moulds that align with your brand’s

aesthetics and performance needs. Our use of advanced cooling techniques also

boosts productivity without compromising quality.

Conclusion

For industries seeking flexibility, premium finish, and operational efficiency,

Leo Precision’s single-stage moulds offer a smart, profitable, and future-ready

packaging solution.