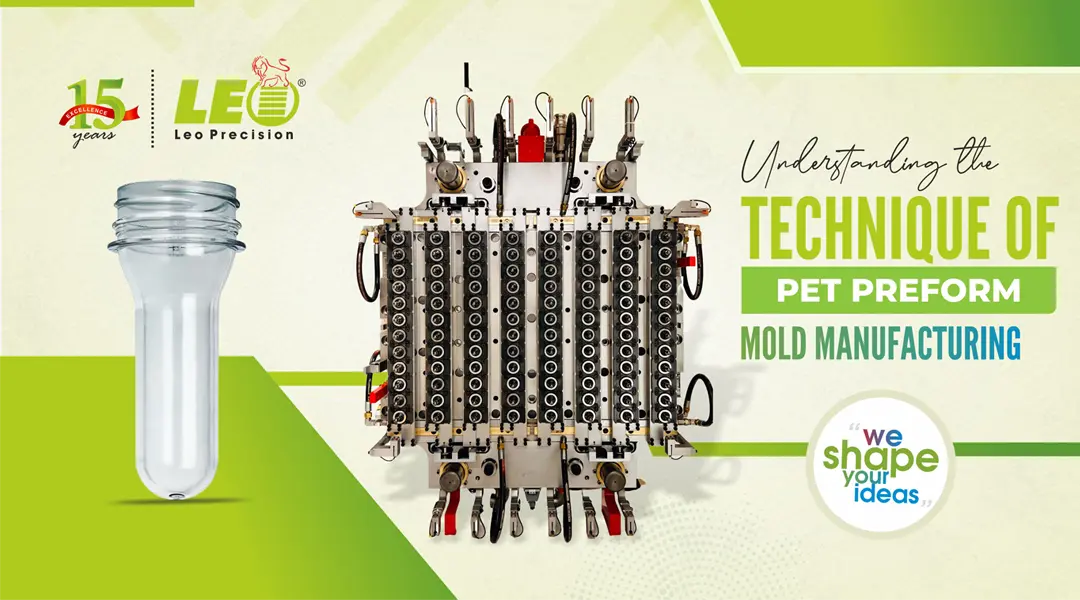

Behind every perfectly shaped PET bottle lies the precision of a PET Preform Mold the unsung

hero of modern packaging. At LEO Precision, we take pride in

mastering this art and science, combining engineering excellence with innovative

design to produce world-class moulds trusted across the globe.

Step-by-Step: The Precision Process

-

1. Design & Simulation: Every mould begins with precision

CAD modeling and flow analysis, ensuring the ideal preform geometry for your

bottle’s performance, weight, and clarity.

-

2. High-Grade Material Selection: We use premium

tool steels and hardened alloys to ensure

strength, longevity, and thermal stability.

-

3. Micro Machining & Polishing: Ultra-precision machining

achieves cavity accuracy down to microns. Each cavity is hand-finished and

polished for flawless surface quality.

-

4. Hot Runner Engineering: LEO’s advanced hot runner

systems deliver balanced melt flow and uniform heating, eliminating flow

lines and defects.

-

5. Testing & Validation: Every mould undergoes rigorous

testing, including cycle time validation, part dimension checks, and

performance trials before delivery.

The Result: Perfect Preforms Every Time

Our moulds ensure high-output production with low maintenance, reduced downtime,

and unmatched consistency. With compatibility across Husky, ASB, SIPA, and

Nissei machines, LEO Precision stands as a global name in

PET packaging technology.

At LEO Precision, every mould tells a story of innovation, craftsmanship, and

commitment to profitability. We don’t just build molds. We build Profitable Packaging Solutions that

power brands across the world.