In the beverage world, success is measured in milliseconds and microns. At LEO

Precision, we live by our philosophy: “You Ideate, We Shape.” We provide high-speed,

high-cavitation mould engineering solutions that allow beverage manufacturers to achieve

maximum throughput with zero compromise on quality.

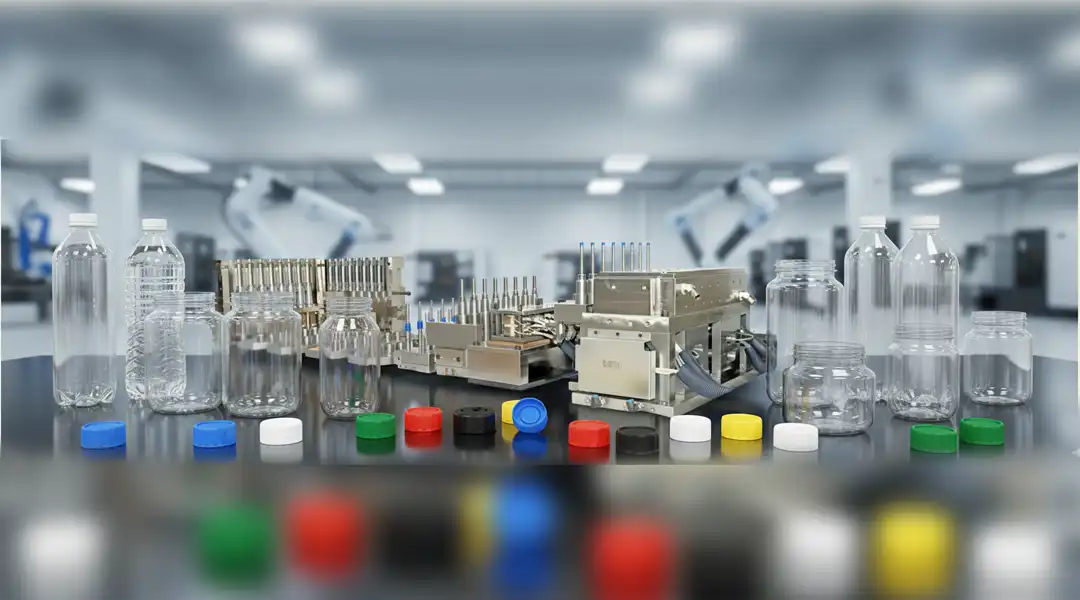

Precision Engineering for Global Beverage Packaging

The beverage industry requires packaging that is lightweight, durable, and perfectly

sealed. LEO Precision engineers moulds that meet the rigorous demands of carbonated soft

drinks (CSD), bottled water, juices, and dairy-based beverages.

Our Beverage Industry Specializations

-

PET Preform Moulds: Engineered for high-speed injection, our

preform moulds ensure uniform material distribution, which is critical for the

subsequent stretch-blow moulding process.

-

High-Speed Closures & Caps: We specialize in multi-cavity

moulds (up to 96 cavities) for CSD caps, water bottle closures, and specialty

dispensing caps with tamper-evident bands.

-

Hot Runner Technology: Our advanced hot runner systems ensure

consistent melt temperature and gate quality, reducing waste and decreasing

cycle times.

-

Lightweighting Solutions: We help manufacturers reduce plastic

consumption by engineering moulds that maintain container strength while using

less resin—supporting both your bottom line and sustainability goals.

Why LEO Precision for Beverage Manufacturing?

-

Shortened Cycle Times: Our optimized cooling channel designs

allow for faster heat dissipation, letting you produce more units per hour than

standard moulds.

-

Durability for High Volumes: Built with premium-grade,

corrosion-resistant steel, our moulds are designed for millions of cycles in

24/7 production environments.

-

Interchangeable Components: We manufacture with such high

precision that 80% of our mould components are interchangeable, allowing for

rapid on-site maintenance without lengthy downtime.

-

Strategic Support: With service hubs in Silvassa, Delhi, and

Chennai, we provide immediate technical assistance to the largest bottling

plants in India.

Shaping the Future of Beverage Packaging

From the initial design of a unique bottle shape to the engineering of a complex

flip-top closure, LEO Precision is your partner in beverage innovation. We don't just

provide a tool; we provide a production advantage.