LEO Precision provides cutting-edge products and services designed for the packaging industry, including:

- Preform Moulds with Hot Runner: High-precision moulds for industries like beverage, pharmaceutical, FMCG, and cosmetics.

- Single Stage Moulds and Blow Moulds(ISBM): Moulds for efficient one-stage container production.

- Caps and Closures Moulds: Tailored moulds for various packaging needs.

- Hot Runner Components: Components that enhance productivity by reducing material waste and improving cycle times.

- OEM Moulds and Conversion Kits: Custom-designed solutions for specific OEM requirements.

LEO Precision serves diverse industries, including:

- Beverage: Advanced packaging solutions for bottling and drinks.

- Pharmaceutical: Precision moulds for medical-grade packaging.

- FMCG: Efficient moulds for fast-moving consumer goods.

- Cosmetics: Custom solutions for high-quality cosmetic packaging.

Preform Moulds with Hot Runner are designed for precise and efficient production of preforms. These moulds are widely used in industries such as:

- Beverage

- Pharmaceutical

- FMCG

- Cosmetics

They ensure minimal material waste and high-quality packaging.

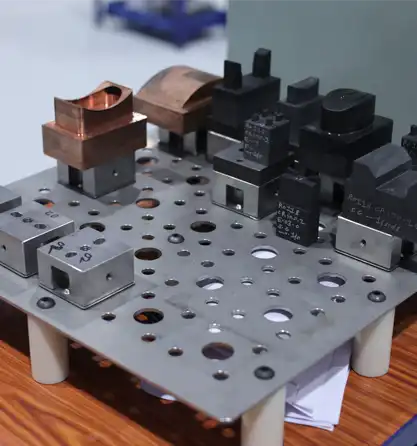

Hot Runner Components play a vital role in improving efficiency by:

- Maintaining the molten state of materials in the runner channels.

- Reducing material waste.

- Accelerating production cycles.

- This results in higher-quality outputs and significant cost savings.

LEO Precision provides custom-designed OEM Moulds and Conversion Kits to meet specific requirements of original equipment manufacturers.

These solutions ensure:

- Seamless compatibility with existing production lines.

- High performance and durability.

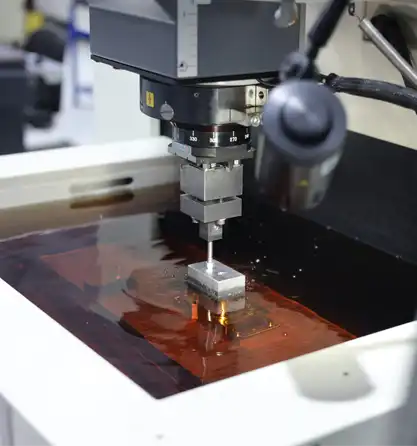

LEO Precision upholds strict quality standards by leveraging:

These solutions ensure:

- A cutting-edge facility equipped with over 50 CNC machines.

- Advanced manufacturing techniques.

- A customer-centric approach focused on delivering innovative solutions.