In the fast-paced world of food processing and packaging, the container is as important

as the content. At LEO Precision, we believe that “You Ideate, We Shape.” Our mould

engineering expertise is the silent engine driving the food industry, ensuring that

every container is safe, leak-proof, and cost-effective.

How Mould Engineering Powers the Food Industry

Mould engineering is not just about creating a shape; it is about high-speed

performance, material science, and uncompromising hygiene. Here is how LEO Precision

contributes to the evolution of food packaging:

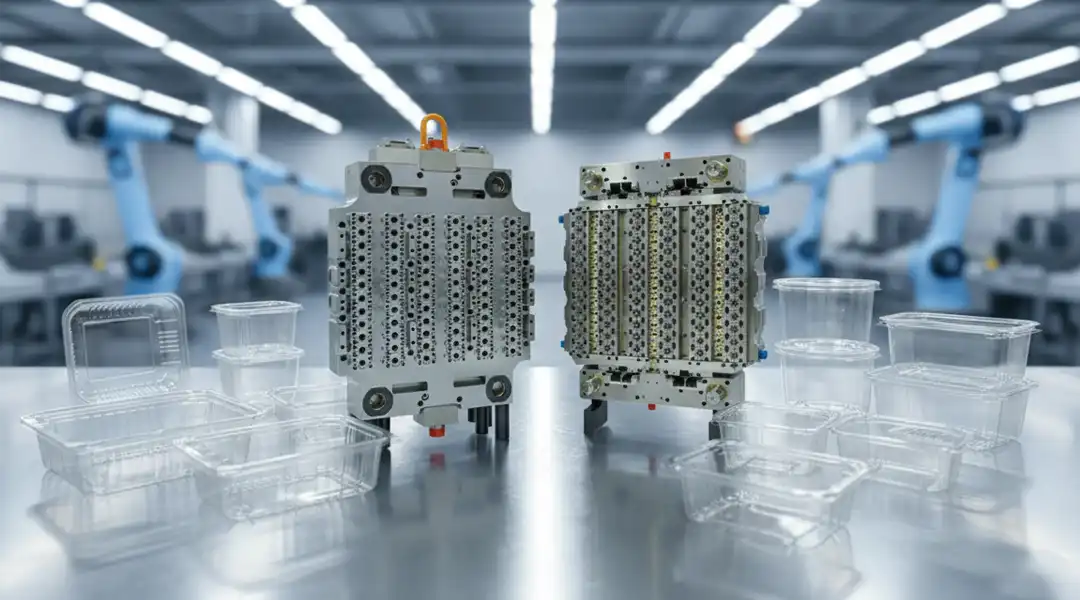

1. Advanced Thin-Wall Injection Moulding (TWIM)

The food industry demands lightweight yet durable packaging to reduce material costs

and carbon footprints. Our engineering team specializes in Thin-Wall Moulds, which

allow for:

-

Reduced Plastic Usage: Creating thinner containers that

maintain structural integrity.

-

Faster Cycle Times: High-speed production to meet the massive

demands of the food supply chain.

-

Energy Efficiency: Optimized cooling systems that lower the

carbon footprint of the manufacturing process.

1. Advanced Thin-Wall Injection Moulding (TWIM)

The food industry demands lightweight yet durable packaging to reduce material costs

and carbon footprints. Our engineering team specializes in Thin-Wall Moulds, which

allow for:

-

Reduced Plastic Usage: Creating thinner containers that

maintain structural integrity.

-

Faster Cycle Times: High-speed production to meet the massive

demands of the food supply chain.

-

Energy Efficiency: Optimized cooling systems that lower the

carbon footprint of the manufacturing process.

2. Leak-Proof Engineering & Airtight Seals

Food preservation depends on the precision of the seal. We engineer moulds for

containers and lids with micron-level accuracy. This ensures:

-

Extended Shelf Life: Preventing oxygen ingress to keep food fresh.

-

Tamper-Evidence: Designing specialized closure systems that provide consumer

safety and brand trust.

-

Stackability: Precision-engineered bases and lids for efficient storage and

transport.

3. Food-Grade Safety & Hygiene Standards

Moulds used in the food industry must operate in clean environments and produce

parts free from contamination.

-

High-Grade Materials: We use premium, corrosion-resistant stainless steel (like

S136) to ensure the moulds do not react with food-grade resins.

-

Lubrication-Free Designs: Our engineering incorporates specialized coatings and

designs that reduce the need for grease, ensuring a sterile production

environment.

Our Food Industry Specializations

-

Disposable Food Containers: Precision moulds for takeaway boxes, microwaveable

containers, and dairy tubs (yogurt/margarine).

-

Multi-Cavity Cap Moulds: High-cavitation systems for edible oil caps, soda closures,

and condiment dispensers.

-

Cutlery & Utensils: High-volume moulds for spoons, forks, and knives used in the

airline and catering sectors.

-

Transparent Packaging: Engineering for high-clarity PP and PET containers that allow

consumers to see product freshness.

Why LEO Precision is the Best Choice for Food Industry?

With a presence in Silvassa, Delhi, and Chennai, LEO Precision provides the local

manufacturing support needed for high-volume food packaging. Our engineering doesn't

just build a mould; it builds a production system that is:

-

High-Volume Ready: Multi-cavity designs (up to 96 cavities) for maximum output.

-

Durable: Built for millions of cycles with minimal maintenance.

-

Sustainable: Optimized for recycled and bio-based plastics.

Transform Your Packaging Ideas into Reality

Consult with our Engineering Experts From initial

design to final production, LEO Precision is your engineering partner. Whether you

are launching a new product or optimizing an existing line with conversion kits, we

deliver the precision the food industry demands.